The student Ming Ma from Rensselaer Polytechnic Institute has developed a new method to manufacture LEDs that are brighter, more energy efficient, and have superior technical properties than those on the market today.

His patent-pending invention holds the promise of hastening the global adoption of LEDs and reducing the overall cost and environmental impact of illuminating our homes and businesses.

Seeking Brighter, Smarter LEDs

Conventional incandescent and fluorescent light sources are increasingly being replaced by more energy-efficient, longer-lived, and environmentally friendlier LEDs, but LEDs still suffer from challenges related to brightness, efficiency, and performance With his project, "Graded-refractive-index (GRIN) Structures for Brighter and Smarter Light-Emitting Diodes," Ma faced these problems head-on and tackled a fundamental, well-known technical shortcoming of LED materials.

LEDs are hampered by low light-extraction efficiency—or the percentage of produced light that actually escapes from the LED chip. Currently, most unprocessed LEDs have a light-extraction efficiency of only 25%, which means 75% of light produced gets trapped within the device itself.

One solution that has emerged is to roughen the surface of LEDs, in order to create nanoscale gaps and valleys that enable more light to escape. While surface roughening leads to brighter and more efficient light emission, the roughening process creates random features on the LED's surface that do not allow for a complete control over other critical device properties such as surface structure and refractive index.

Freeing Trapped Light with GRIN LEDs

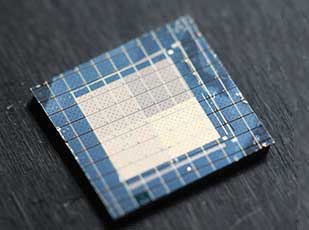

Ma's solution to this problem was to create an LED with well-structured features on the surface to minimize the amount of light that gets reflected back into the device, and thus boost the amount of light emitted. He invented a process for creating LEDs with many tiny star-shaped pillars on the surface. Each pillar is made up of five nanolayers specifically engineered to help "carry" the light out of the LED material and into the surrounding air.

Ma's patent-pending technology, called GRIN (graded-refractive-index) LEDs, has demonstrated a light-extraction efficiency of 70%, meaning 70% of light escaped and only 30% was left trapped inside the device—a huge improvement over the 25% light-extraction efficiency of most of today's unprocessed LEDs. In addition, GRIN LEDs also have controllable emission patterns, and enable a more uniform illumination than today's LEDs.

Overall, Ma's innovation could lead to entirely new methods for manufacturing LEDs with increased light output, greater efficiency, and more controllable properties than both surface-roughened LEDs and the LEDs currently available in the marketplace.

For this innovation, Ma, a doctoral student in the Department of Materials Science and Engineering, has been named the winner of the prestigious 2013 $30,000 Lemelson-Rensselaer Student Prize. He is among the three 2013 $30,000 Lemelson-MIT Collegiate Student Prize winners announced today.

"For more than 175 years, Rensselaer has produced some of the world's most successful engineers and scientists, explorers and scholars, innovators and entrepreneurs. Doctoral student Ming Ma, with his groundbreaking invention of GRIN LEDs, honors and continues this tradition of excellence," said David Rosowsky, dean of the School of Engineering at Rensselaer. "Rensselaer and the School of Engineering offer a hearty congratulations to Ming for his achievement. We also applaud all of the winners, finalists, and entrants of the Lemelson-MIT Collegiate Student Prize for using their talent and passion to engineer a better world and a better tomorrow."

Ma is the seventh recipient of the Lemelson-Rensselaer Student Prize. First given in 2007, the prize is awarded annually to a Rensselaer senior or graduate student who has created or improved a product or process, applied a technology in a new way, redesigned a system, or demonstrated remarkable inventiveness in other ways.

|